As industries move toward automation and smart infrastructure, the demand for reliable and precise flow control solutions continues to grow. Valves play a critical role in managing liquids, slurry, and process media across water systems and industrial pipelines. Among the most dependable solutions available today are high-performance electric slide gate valves, designed specifically for automated flow control.

This article explains what electric slide gate valves are, how they work, their advantages, key applications, and how they compare with another popular automated valve—the motorized butterfly valve.

Understanding Electric Slide Gate Valves

An electric slide gate valve is a flow control device that uses a flat gate to open or close the flow path inside a pipeline. The gate moves vertically and is powered by an electric actuator, eliminating the need for manual operation. This makes the valve ideal for automated systems where precision, safety, and consistency are required.

These valves are commonly used for on-off and isolation duties, especially in applications involving water, wastewater, slurry, and industrial fluids.

How Electric Slide Gate Valves Work

The working principle of an electric slide gate valve is straightforward:

-

The electric actuator receives a control signal.

-

The actuator moves the gate upward to allow flow or downward to stop it.

-

Once fully open or closed, limit switches stop the actuator to prevent over-travel.

-

The result is smooth, controlled, and repeatable valve operation.

This simple yet effective mechanism makes electric slide gate valves highly reliable for automated flow control.

Key Features of High-Performance Electric Slide Gate Valves

High-performance electric slide gate valves are engineered to handle demanding operating conditions. Key features include:

-

Electric Actuator Operation for automation and remote control

-

Robust Body Construction for durability and long service life

-

Tight Shut-Off Capability to minimize leakage

-

Low Operating Torque for smooth performance

-

Minimal Maintenance Requirements due to simple design

These features make them suitable for both continuous and intermittent operation in industrial environments.

Benefits of Electric Slide Gate Valves in Automation

1. Precise Automated Control

Electric slide gate valves integrate easily with PLC, SCADA, and control panels. This allows operators to manage flow remotely, improving efficiency and safety.

2. Reliable Flow Isolation

The gate design provides excellent sealing when closed, making these valves ideal for isolation applications.

3. Reduced Manual Effort

Electric actuation removes the need for handwheels or levers, which is especially helpful for large-size valves or inaccessible installations.

4. Faster Operation

Compared to manual valves, electric slide gate valves offer quicker opening and closing, reducing downtime.

5. Long-Term Cost Savings

Lower maintenance needs and longer service life help reduce operating costs over time.

Applications of Electric Slide Gate Valves

Water Treatment Plants

Electric slide gate valves are widely used to control water flow during filtration, treatment, and distribution processes.

Wastewater and Sewage Systems

They perform well in handling wastewater, sludge, and abrasive media, where strong shut-off and durability are essential.

Industrial Pipelines

Used across chemical plants, power stations, cement industries, and mining operations for safe flow control.

Pumping Stations

These valves are installed before or after pumps to isolate flow during maintenance or emergencies.

Electric Slide Gate Valves in Automated Systems

Automation is becoming a standard requirement in modern facilities. Electric slide gate valves support automation by offering:

-

Consistent valve positioning

-

Remote operation and monitoring

-

Reduced human error

-

Improved system efficiency

Their compatibility with automated control systems makes them a future-ready solution for industries aiming to modernize operations.

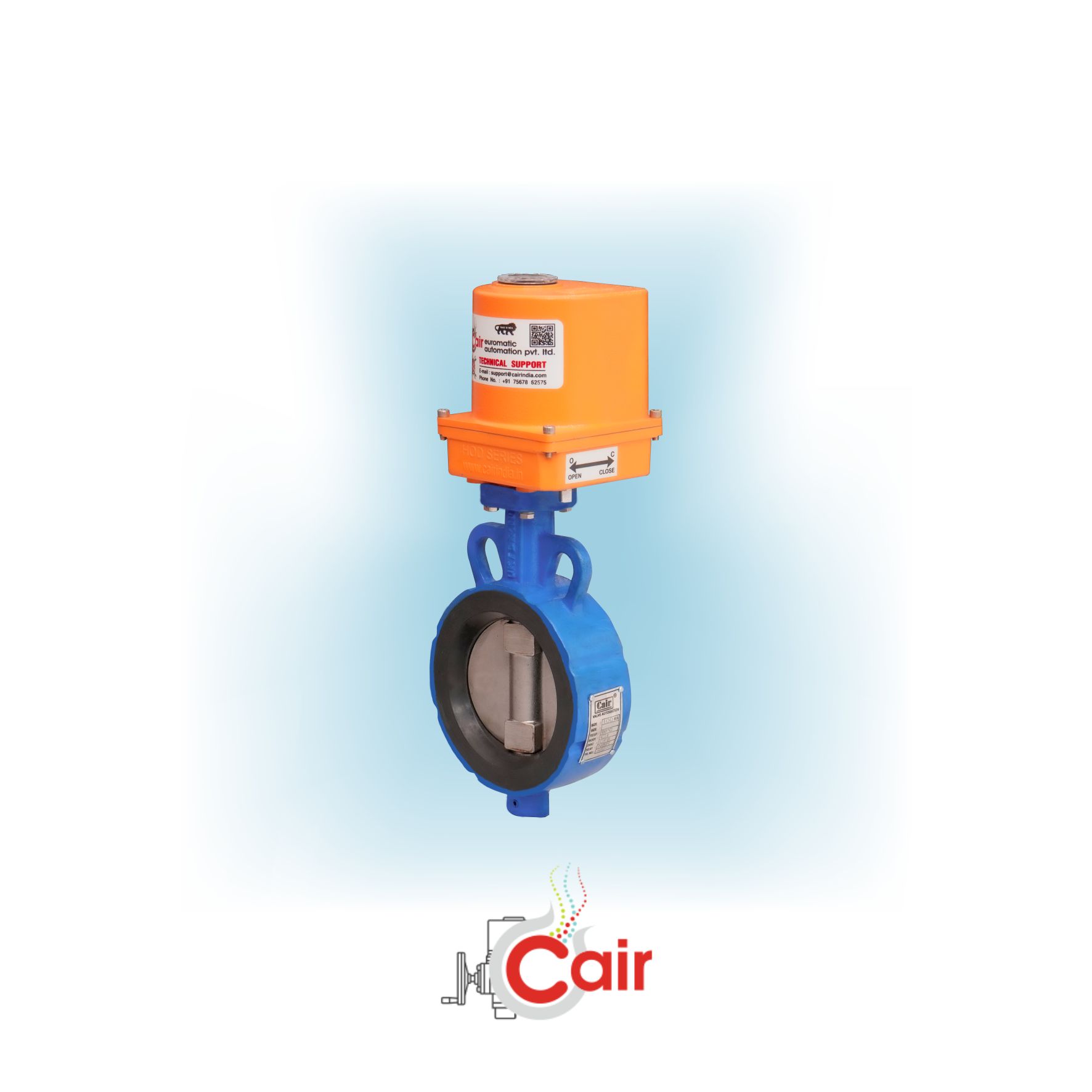

Introduction to Motorized Butterfly Valves

Alongside electric slide gate valves, motorized butterfly valves are also commonly used in automated flow control systems. A motorized butterfly valve operates using an electric actuator that rotates a disc inside the valve body by 90 degrees to control flow.

These valves are compact, lightweight, and efficient, making them suitable for a wide range of applications.

How Motorized Butterfly Valves Work

-

The electric actuator rotates the valve disc to open or close the flow path.

-

The valve provides quick operation with minimal energy consumption.

-

The actuator ensures accurate positioning for both on-off and throttling applications.

Motorized butterfly valves are especially effective where space is limited and fast operation is required.

Benefits of Motorized Butterfly Valves

Benefits of Motorized Butterfly Valves

Motorized butterfly valves offer several advantages, including:

-

Compact Design that saves installation space

-

Fast Operation with quarter-turn movement

-

Low Pressure Drop in fully open position

-

Ease of Automation with electric actuators

-

Cost-Effective Solution for large pipelines

These benefits make them popular in water supply systems, HVAC networks, and industrial pipelines.

Electric Slide Gate Valve vs Motorized Butterfly Valve

Both valve types serve important roles in automated flow control, but their functions differ.

Electric Slide Gate Valve

-

Best suited for isolation and shut-off

-

Ideal for slurry and wastewater

-

Vertical gate movement

-

Excellent sealing performance

Motorized Butterfly Valve

-

Suitable for flow regulation and throttling

-

Compact and lightweight

-

Quarter-turn disc operation

-

Best for clean water and low-solid fluids

In many systems, electric slide gate valves and motorized butterfly valves are used together to achieve optimal performance.

Choosing the Right Valve for Your Application

When selecting between an electric slide gate valve and a motorized butterfly valve, consider:

-

Type of media (clean water, slurry, chemicals)

-

Pressure and temperature requirements

-

Need for isolation or flow regulation

-

Available installation space

-

Level of automation required

Choosing the right valve ensures efficiency, safety, and long-term reliability.

Maintenance and Performance Reliability

High-performance electric slide gate valves are designed for low maintenance. Routine inspection of the actuator, seals, and gate movement helps maintain consistent performance. Similarly, motorized butterfly valves require minimal maintenance due to their simple design and fewer moving parts.

Proper installation and periodic checks significantly extend valve life.

Future of Automated Flow Control

With growing emphasis on automation, smart cities, and industrial efficiency, automated valves are becoming essential. Electric slide gate valves and motorized butterfly valves will continue to play a key role in modern pipeline systems by offering:

-

Enhanced operational control

-

Improved safety standards

-

Reduced energy consumption

-

Long-term cost efficiency

Conclusion

High-Performance Electric Slide Gate Valves for Automated Flow Control provide a reliable and efficient solution for modern water and industrial applications. Their robust construction, precise automation, and dependable shut-off make them ideal for demanding environments.

When combined with complementary solutions like the motorized butterfly valve, they help create fully automated, efficient, and safe pipeline systems. As industries continue to adopt automation, these valves will remain essential components in achieving accurate and dependable flow control.

![Epoxy Curing Agents Market Growth Analysis Report | Industry Status, Market Opportunities, Key Challenges, Competitive Strategies, Revenue Breakdown, and Forecast Outlook [2025–2034]](https://driftelano.com/wp-content/uploads/2025/12/Epoxy-Curing-Agents-Market.jpg)

![EMI Shielding Market Insights and Analysis [2025–2034] | Industry Performance, Growth Opportunities, Risk Factors, Strategic Developments, and Long-Term Market Projections](https://driftelano.com/wp-content/uploads/2025/12/EMI-Shielding-Market.jpg)

![Dimethyl Ether (DME) Market [Latest Reports] | Business Environment Analysis, Corporate Strategies, Competitive Benchmarking, Investment Trends, and Emerging Market Developments [2025–2034]](https://driftelano.com/wp-content/uploads/2025/12/Dimethyl-Ether-DME-Market.png)

Leave a Reply